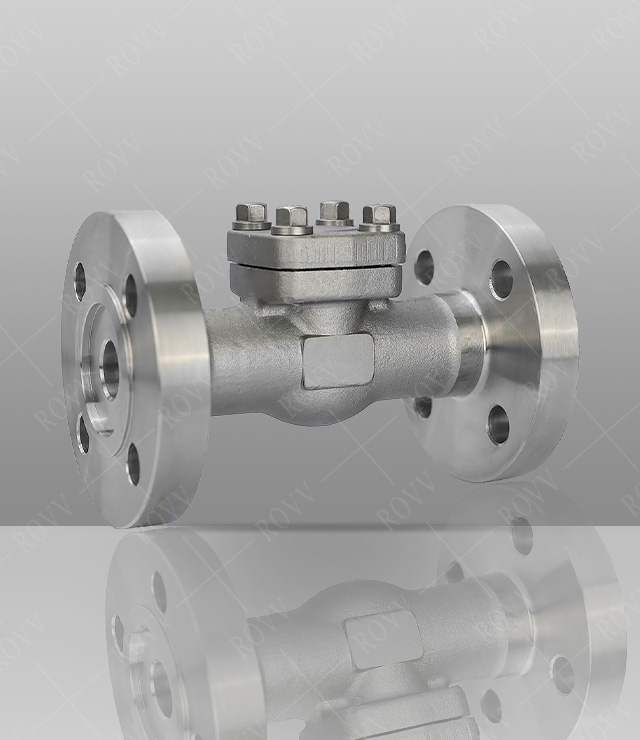

Fluorine-lined swing check valve

Technical Parameters

Product model: H44F46

Nominal diameter: DN15~DN500

Structural form: swing type

Nominal pressure: PN0.6MPa~1.0MPa~1.6MPa

Connection method: flange

Applicable temperature: -50oC~+150oC

Drive mode: medium drive

Connection material: cast iron, cast steel, stainless steel

Applicable medium: aqua regia, sulfuric acid, hydrochloric acid, hydrofluoric acid, etc.

Product overview

H44F46 fluorine-lined swing check valve is suitable for various concentrations of aqua regia, sulfuric acid, hydrochloric acid, hydrofluoric acid and various organic acids, strong acids, strong oxidants at -50 ° C ~ 150 ° C, FEP is also suitable for various concentrations Strong alkali organic solvents and other corrosive gases and liquid media are used on the pipeline. Its main function is to prevent the backflow of the medium.

Standard specification

Design and manufacturing standards: GB/T 12236

Structure length standard: GB/T 12221-2005Connection flange standard: GB/T 9113, HG20592-97

Pressure temperature rating: GB/T 12224-2005

Test and inspection standard: GB/T 13927-2008

Materials of main components

| Serial number | Part Name | Grey cast iron | Cast steel | Stainless steel | Ultra Low Carbon Stainless Steel | ||

| Z | C | P | R | PL | RL | ||

| 1 | Body, bonnet | HT250 | WCB | CF8 | CF8M | CF3 | CF3M |

| 2 | Lining/Bonnet | Hard rubber lining (NR) FEP (F46) PCTFE (F3) PFA (soluble polytetrafluoroethylene) | |||||

| 3 | Shaft, disc (plate) | 1 Cr13/35WCB 1Cr18Ni9/CF8 00Cr17Ni14Mo2/CF3M | |||||

| 4 | Bolt | 35 | 35 | 1Cr17Ni2 | 1Cr17Ni2 | 1Cr18Ni9Ti | 1Cr18Ni9Ti |

| 5 | Nut | 45 | 45 | 0Cr18Ni9 | 0Cr18Ni9 | 0Cr18Ni9 | 0Cr18Ni9 |

Main Dimensions PN0.6MPa

| Nominal diameter | Standard value | Reference | |||||||||

| DN(mm) | NPS(inch) | L | D | D1 | D2 | f | b | Z-Φd | B | H | W(kg) |

| 15 | 1/2 | 130 | 80 | 55 | 40 | 2 | 12 | 4-Φ12 | 105 | 55 | 4 |

| 20 | 3/4 | 150 | 90 | 65 | 50 | 2 | 14 | 4-Φ12 | 115 | 58 | 5 |

| 25 | 1 | 160 | 100 | 75 | 60 | 2 | 14 | 4-Φ12 | 128 | 60 | 6 |

| 32 | 1 1/4 | 180 | 120 | 90 | 70 | 2 | 16 | 4-Φ14 | 145 | 75 | 7 |

| 40 | 1 1/2 | 200 | 130 | 100 | 80 | 3 | 16 | 4-Φ14 | 160 | 82 | 8 |

| 50 | 2 | 230 | 140 | 110 | 90 | 3 | 16 | 4-Φ14 | 178 | 95 | 10 |

| 65 | 2 1/2 | 290 | 160 | 130 | 110 | 3 | 16 | 4-Φ14 | 205 | 105 | 20 |

| 80 | 3 | 310 | 185 | 150 | 125 | 3 | 18 | 4-Φ18 | 230 | 120 | 25 |

| 100 | 4 | 350 | 205 | 170 | 145 | 3 | 18 | 4-Φ18 | 255 | 135 | 30 |

| 125 | 5 | 400 | 235 | 200 | 175 | 3 | 20 | 8-Φ18 | 305 | 158 | 50 |

| 150 | 6 | 480 | 260 | 225 | 200 | 3 | 20 | 8-Φ18 | 345 | 180 | 65 |

| 200 | 8 | 495 | 315 | 280 | 255 | 3 | 22 | 8-Φ18 | 415 | 215 | 137 |

| 250 | 10 | 622 | 370 | 335 | 310 | 3 | 24 | 12-Φ18 | 490 | 240 | 150 |

| 300 | 12 | 698 | 435 | 395 | 362 | 4 | 24 | 12-Φ23 | 540 | 265 | 185 |

| 350 | 14 | 787 | 485 | 445 | 412 | 4 | 26 | 12-Φ23 | 585 | 300 | 215 |

| 400 | 16 | 914 | 535 | 495 | 462 | 4 | 28 | 16-Φ23 | 625 | 360 | 244 |

| 450 | 18 | 978 | 590 | 550 | 518 | 4 | 28 | 16-Φ23 | 680 | 385 | 276 |

| 500 | 20 | 978 | 640 | 600 | 568 | 4 | 30 | 16-Φ23 | 740 | 415 | 315 |