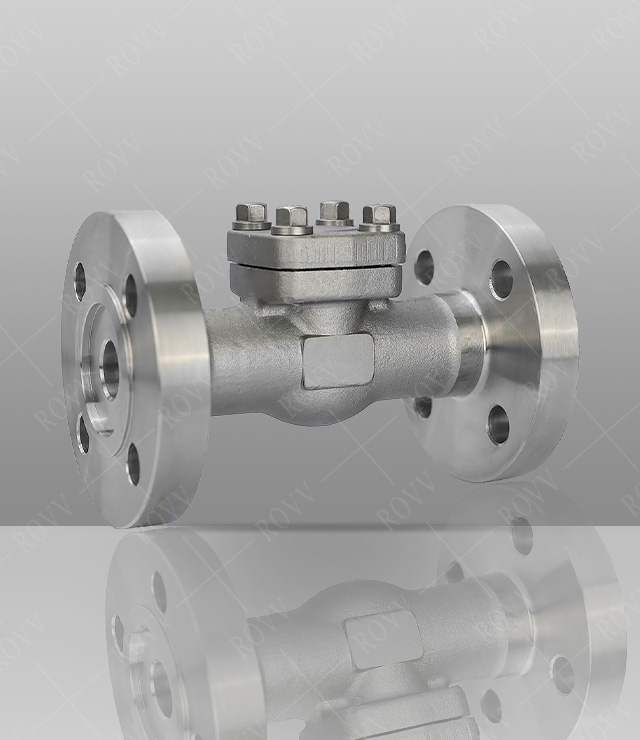

Vertical check valve

Technical Parameters

Product model: H42W/H

Nominal diameter: DN15~200mm

Nominal pressure: PN1.6~4.0MPa

Operating temperature: -29°C~200°C

Applicable medium: water, steam, oil, nitric acid, acetic acid

Product Description

The stainless steel vertical check valve is normally closed. Due to the pressure of the medium at the inlet end of the pipeline, the valve is opened by overcoming the resistance of the spring. When the medium pressure at the inlet end is lower than that at the outlet end, the spring pushes the valve core to the valve seat to close the valve, preventing the medium from flowing back, so it acts as a check. The valve can be installed vertically or horizontally due to the spring-supported valve core.

Product Features

1. The sealing pair of the stainless steel vertical check valve is advanced and reasonable. The sealing surface of the valve disc and valve seat is made of iron-based alloy or Stellite cobalt-based hard alloy surfacing surface, which is wear-resistant, high-temperature resistant and corrosion-resistant. , Good scratch resistance and long service life.

2. The stainless steel vertical check valve is designed and manufactured according to the standard, and can adopt various piping flange standards and flange sealing types to meet various engineering needs and user requirements. The valve body has a complete variety of materials, and the gasket can be reasonably selected according to the actual working conditions or user requirements, and can be suitable for various pressure, temperature and medium working conditions.

Material of main parts

|

Part Name |

Body, disc |

Pilot valve |

Sealing surface |

|

H42W-16C |

Carbon steel |

Carbon steel |

Carbon steel |

|

H42W-16P |

Chrome-nickel-titanium stainless steel |

chrome-nickel-titanium stainless steel |

Chrome-nickel-titanium stainless steel |

|

H42W-25P |

|||

|

H42W-40P |

|||

|

H42W-25R |

Chrome-nickel-titanium stainless steel |

chrome-nickel-titanium stainless steel |

Chrome-nickel-titanium stainless steel |

|

H42W-40R |

|||

|

H42Y-40 |

Carbon steel |

Carbon steel |

Hardfacing carbide |

Main performance parameters

|

Model |

PN(MPa) |

Test pressureP3(MPa) |

Proper temperature(℃) |

Applicable media |

|

|

Case |

Seal |

||||

|

H42W-16C |

1.6 |

2.4 |

1.76 |

≤425 |

Water, oil |

|

H42W-16P |

≤200 |

Weak corrosive medium |

|||

|

H42W-25P |

2.5 |

3.75 |

2.75 |

||

|

H42W-25R |

Corrosive media |

||||

|

H42W-40P |

4.0 |

6.0 |

4.4 |

Weak corrosive medium |

|

|

H42W-40R |

Corrosive media |

||||

|

H42Y-40 |

Water, oil |

||||

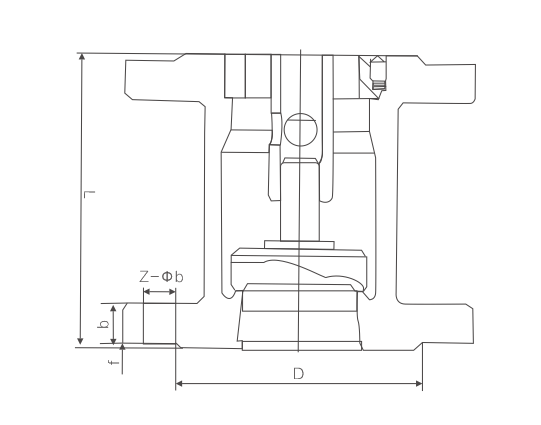

Main external connection dimensions and weight(1.6MPa)

| Size | DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 |

| L | mm | 105 | 105 | 105 | 150 | 160 | 170 | 180 | 200 | 210 | 275 | 300 | 380 |

| D | mm | 95 | 105 | 115 | 135 | 145 | 160 | 180 | 195 | 215 | 245 | 280 | 335 |

| WT | kg | - | - | - | - | - | 7.9 | 11 | 12 | 19.5 | 36 | 47 | 65 |

Main external connection dimensions and weight(2.5MPa)

| Size | DN | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 |

| L | mm | 105 | 105 | 150 | 160 | 170 | 180 | 200 | 210 | 275 | 300 | 380 |

| D | mm | 105 | 115 | 135 | 145 | 160 | 180 | 195 | 230 | 275 | 300 | 360 |

| WT | kg | - | - | - | - | 7.9 | 11 | 12 | 20 | 38 | 48 | 70 |

Main external connection dimensions and weight(4.0MPa)

| Size | DN | 50 | 65 | 80 | 100 | 125 | 150 | 200 |

| L | mm | 170 | 180 | 200 | 210 | 275 | 300 | 380 |

| D | mm | 160 | 180 | 195 | 230 | 270 | 300 | 375 |

| WT | kg | 7.9 | 11 | 12 | 20 | 38 | 48 | 72 |