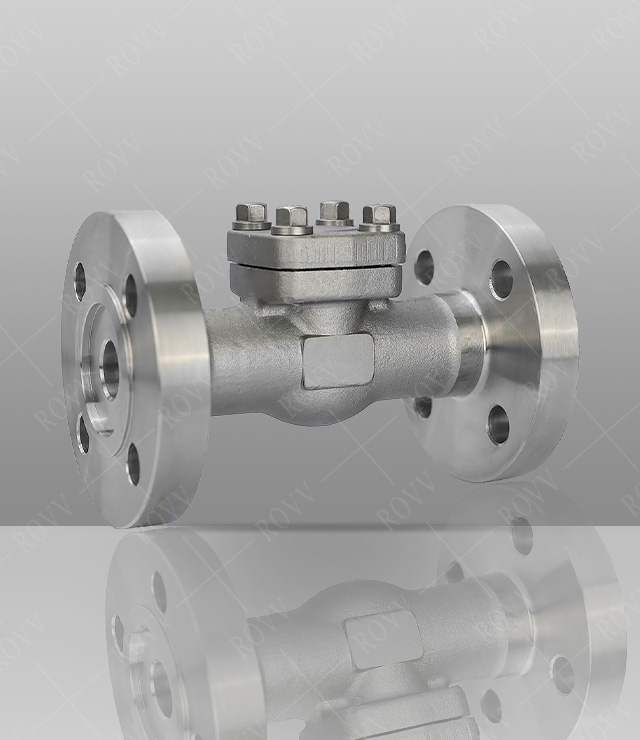

Cast steel lift check valve

Technical Parameters

Product model: H41W/H

Nominal diameter: DN15~300mm

Nominal pressure: PN1.6~2.5MPa

Operating temperature: -29°C~425°C

Applicable medium: water, steam, oil, etc.

Product Description

The body structure of the cast steel lift check valve adopts the valve body of the globe valve, and the valve disc moves up and down along the line in the channel. Straight-through lift check valves can generally only be installed in horizontal pipelines, while vertical lift check valves are generally installed in vertical pipelines. The products are widely used in pipelines of various working conditions such as petroleum, chemical, pharmaceutical, and electric power industries.

Product Features

1. The design and manufacture of check valve products are designed and manufactured according to GB/T 12235, with reliable sealing and excellent performance.

2. The sealing surfaces of the valve disc and valve seat are made of stellite cobalt-based hard alloy surfacing, which is wear-resistant, high-temperature resistant, has good scratch resistance and long service life.

3. Various piping flange standards and flange sealing surface types can be used to meet various engineering needs and user requirements.

4. The material of the valve body is complete, and the packing and gasket are reasonably selected according to the actual working conditions or user requirements, which can be applied to various pressure, temperature and medium working conditions.

5. Check valves with different structural forms and connection forms can be manufactured according to user requirements, and used for various equipment.

Main performance specifications

| Model | H41H-16C~100 | H41Y-16C~100 | H41W-16P~100 | |

| PN(MPa) | 1.6~10.0 | |||

| Proper temperature(℃) | ≤425 | ≤150 | ||

| Applicable media | Water, steam, oil | Weak corrosive medium | ||

| Material | Body, bonnet | Carbon steel | chrome-nickel-titanium stainless steel | |

| Sealing surface | Surfacing chrome stainless steel | Hardfacing carbide | chrome-nickel-titanium stainless steel | |

| Gasket | Steel belt graphite ginseng winding | PTFE | ||

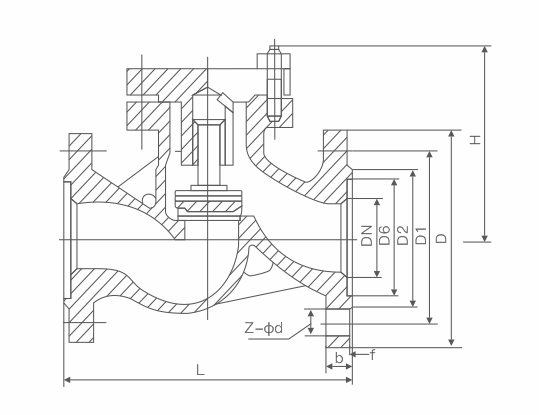

Main external connection dimensions

| DN | Main external connection dimensions | ||||||

| L | D | D1 | D2 | b | Z-d | H | |

| H41H-16C H41W-16C H41W-16P H41W-16R H41W-16I | |||||||

| 15 | 130 | 95 | 65 | 45 | 14 | 4-14 | 77 |

| 20 | 150 | 105 | 75 | 55 | 14 | 4-14 | 77 |

| 25 | 160 | 115 | 85 | 65 | 14 | 4-14 | 80 |

| 32 | 180 | 135 | 100 | 75 | 16 | 4-18 | 85 |

| 40 | 200 | 145 | 110 | 85 | 16 | 4-18 | 95 |

| 50 | 230 | 160 | 125 | 100 | 16 | 4-18 | 105 |

| 65 | 290 | 180 | 145 | 120 | 18 | 4-18 | 120 |

| 80 | 310 | 195 | 160 | 135 | 20 | 8-18 | 130 |

| 100 | 350 | 215 | 180 | 155 | 20 | 8-18 | 140 |

| 125 | 400 | 245 | 210 | 185 | 22 | 8-18 | 155 |

| 150 | 480 | 280 | 240 | 210 | 24 | 8-23 | 180 |

| 200 | 600 | 335 | 295 | 265 | 26 | 12-23 | 215 |

| 250 | 730 | 405 | 355 | 320 | 30 | 12-25 | 260 |

| 300 | 850 | 460 | 410 | 375 | 34 | 12-25 | 315 |

| H41H-25 H41W-25 H41W-25P H41W-25R H41W-25I | |||||||

| 15 | 130 | 95 | 65 | 45 | 16 | 4-14 | 100 |

| 20 | 150 | 105 | 75 | 55 | 16 | 4-14 | 105 |

| 25 | 160 | 115 | 85 | 65 | 16 | 4-14 | 120 |

| 32 | 180 | 135 | 100 | 78 | 18 | 4-18 | 130 |

| 40 | 200 | 145 | 110 | 85 | 18 | 4-18 | 135 |

| 50 | 230 | 160 | 125 | 100 | 20 | 4-18 | 149 |

| 65 | 290 | 180 | 145 | 120 | 22 | 8-18 | 160 |

| 80 | 310 | 195 | 160 | 135 | 22 | 8-18 | 169 |

| 100 | 350 | 230 | 190 | 160 | 24 | 8-23 | 194 |

| 125 | 400 | 270 | 220 | 180 | 28 | 8-25 | 222 |

| 150 | 480 | 300 | 250 | 218 | 30 | 8-25 | 255 |

| 200 | 600 | 360 | 310 | 278 | 34 | 12-25 | 305 |

| 250 | 730 | 425 | 370 | 332 | 36 | 12-30 | 355 |

| 300 | 850 | 485 | 430 | 390 | 40 | 16-30 | 410 |