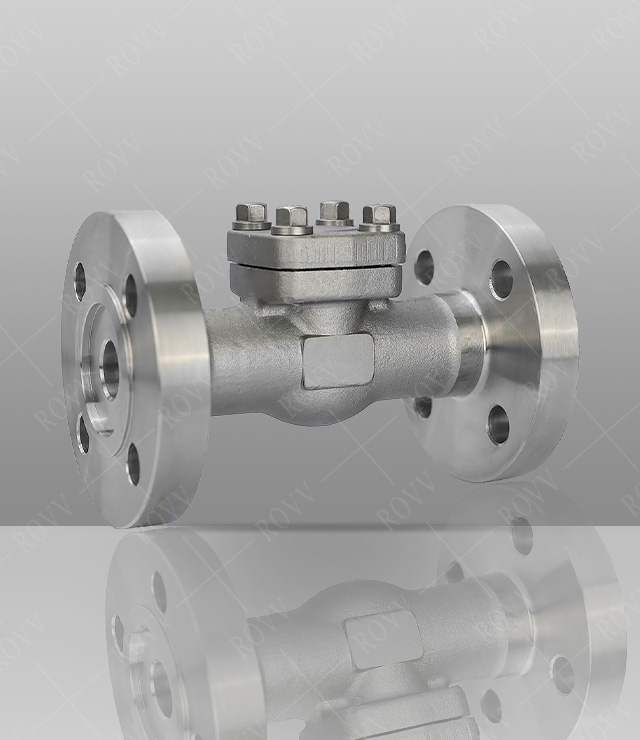

Wafer lift check valve

Technical Parameters

Product model: H71W/H/Y

Nominal diameter: DN 50~1200mm

Nominal pressure: PN1.6~4.0MPa

Working temperature: ≤350℃

Applicable medium: water, oil, steam, acidic medium, etc.

Product Description

Wafer connection lift check valve, also known as wafer check valve, is mainly composed of valve body, valve disc, spring, etc. It can be installed in various pipeline systems horizontally or vertically to prevent the backflow of the medium. The advantages of small size and light weight. The valve disc of the valve closes quickly, the water hammer pressure is small, the flow channel is smooth, the fluid resistance is small, the action is sensitive, and the sealing performance is good. It is mainly suitable for clean medium, not suitable for pipelines containing solid particles and high viscosity medium. It can be installed at the outlet of the pump to avoid water hammer, water hammer sound and destructive impact, achieve the purpose of preventing backflow and protecting equipment, and has better energy saving effect.

Product Features

1. The product structure is short in length, small in size and light in weight.

2. The sealing flap can choose soft sealing or hard sealing material according to different working conditions, and the sealing performance is good.

3. Both horizontal and vertical pipes can be used, and the installation is convenient.

4. The valve disc closes quickly and the water hammer pressure is small.

5. The material of the parts and the form and size of the valve end face can be reasonably selected according to the actual working conditions or user requirements to meet various engineering needs.

Material of main parts

|

Specifications |

Body |

Disc |

Spring |

|

H71H-16Q、H71H-25Q |

QT400-15 |

25 |

50CrCA |

|

H71W-25H、H71W-40H |

2Cr13 |

1Cr13 |

1Cr18Ni9Ti |

|

H71W-16P、H71W-25P |

ZG1Cr18Ni9Ti |

1Cr18Ni9Ti |

1Cr18Ni9Ti |

Main performance specifications

|

Model |

PN(MPa) |

Test pressure PS(MPa) |

Operating temperature(℃) |

Applicable media |

|

|

Case |

Seal |

||||

|

H71W-16T |

1.6 |

2.4 |

1.76 |

≤200 |

Water, steam, oil, etc. |

|

H71H-25Q |

2.5 |

3.75 |

2.75 |

≤235 |

|

|

H71W-25H |

≤300 |

||||

|

H71W-25P |

≤200 |

Corrosive media such as nitric acid |

|||

|

H71W-40H |

4.0 |

6.0 |

4.4 |

≤300 |

Water, steam, oil, etc. |

|

H71W-40P |

≤200 |

Corrosive media such as nitric acid |

|||

Main external connection dimensions

|

DN(mm) |

L |

D |

D1 |

D3 |

D2 |

WT (Kg) |

|

15 |

28 |

52 |

15 |

44 |

25 |

0.12 |

|

20 |

28 |

62 |

19 |

52 |

30 |

0.25 |

|

25 |

30 |

72 |

24 |

60 |

36 |

0.34 |

|

32 |

35 |

83 |

31 |

72 |

43 |

0.53 |

|

40 |

40 |

93 |

39 |

74 |

52 |

0.80 |

|

50 |

45 |

107 |

48 |

98 |

62 |

1.2 |

|

65 |

56 |

124 |

63 |

117 |

75 |

2.2 |

|

80 |

60 |

138 |

78 |

128 |

90 |

3.1 |

|

100 |

70 |

162 |

98 |

/ |

112 |

5.7 |

|

125 |

80 |

190 |

123 |

/ |

132 |

10 |

|

150 |

100 |

220 |

148 |

/ |

158 |

14 |

|

200 |

110 |

270 |

198 |

/ |

208 |

24 |

|

250 |

132 |

328 |

248 |

/ |

208 |

35 |