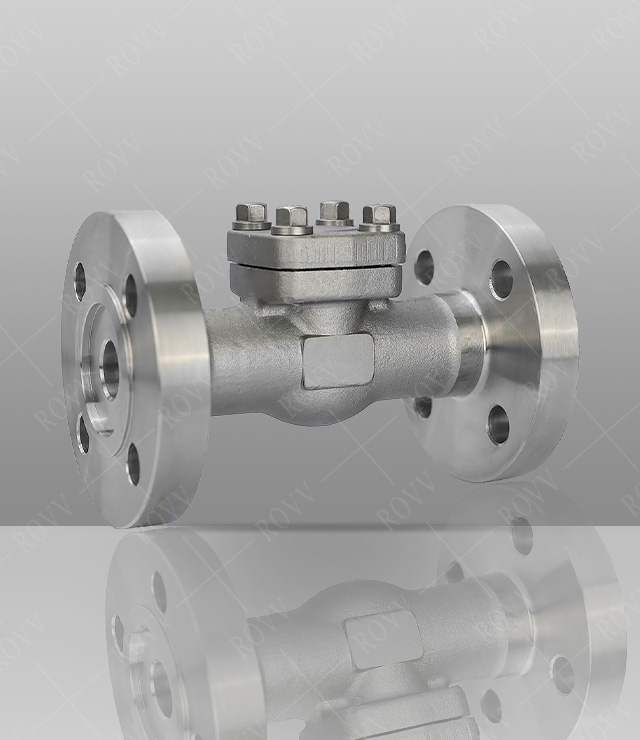

Fluorine lined straight lift check valve

Technical Parameters

Product model: H41F46

Nominal diameter: DN15mm-2500mm

Nominal pressure: PN0.6 MPa ~1.6 MPa

Body test: PN×1.5 MPa

Seal detection: PN×1.1 MPa

Test standard: GB/T13927-2008

Lining inspection: EDM inspection

Disc Material: Carbon Steel Fully Coated with Fluoroplastic

Applicable temperature: ≤80℃, ≤100℃, ≤120℃, ≤150℃

Product Description

The Fluorine lined straight lift check valve is also called a check valve. The internal flow channel seal of the valve body is fully lined with PTFE, which has the characteristics of high strength and good corrosion resistance. It is suitable for various concentrations of aqua regia, sulfuric acid, hydrochloric acid, hydrofluoric acid and various organic acids, strong acids and strong oxidants at temperatures of -50℃~150℃. FEP is also suitable for various concentrations of strong alkali organic solvents and other corrosion products. It is used to prevent the backflow of the medium on the pipeline of the inert gas and liquid medium.

Material of main parts

|

NO |

Part Name |

Grey cast iron |

Cast steel |

Stainless acid-resistant cast steel |

Ultra-low carbon stainless acid-resistant cast steel |

||

|

Z |

C |

P |

R |

PL |

RL |

||

|

1 |

Body/bonnet |

HT250 |

WCB |

CF8 |

CF8M |

CF3 |

CF3M |

|

2 |

Disc/Stem |

35 |

1Cr13 |

1Cr18Ni9 |

1Cr18Ni12Mo2Ti |

00Cr18Ni10 |

00Cr17Ni14Mo2 |

|

3 |

Lining/Seat |

PCTEF(F3),FEP(F46),PFA(SolubleF4),PP,PO |

|||||

|

4 |

Fastening bolts |

WCB |

1Cr17Ni2 |

1Cr18Ni9Ti |

|||

|

5 |

Nut |

PTFE(F4) |

CF8 |

CF8 |

|||

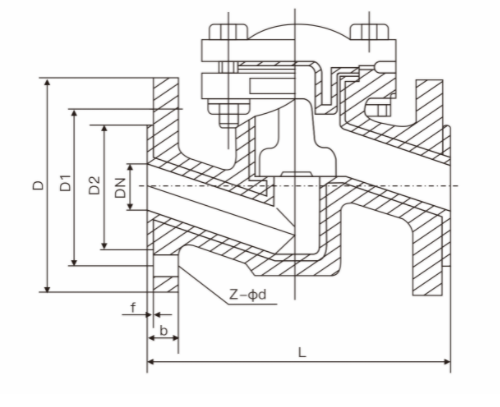

Main external connection dimensions PN0.6MPa

|

Nominal Diameter |

Standard value |

Reference value |

|||||||||

|

DN(mm) |

NPS(inch) |

L |

D |

D1 |

D2 |

f |

b |

Z-Φd |

B |

H |

W(kg) |

|

15 |

1/2 |

130 |

80 |

55 |

40 |

2 |

12 |

4-Φ12 |

105 |

55 |

4 |

|

20 |

3/4 |

150 |

90 |

65 |

50 |

2 |

14 |

4-Φ12 |

115 |

58 |

5 |

|

25 |

1 |

160 |

100 |

75 |

60 |

2 |

14 |

4-Φ12 |

128 |

60 |

6 |

|

32 |

1 1/4 |

180 |

120 |

90 |

70 |

2 |

16 |

4-Φ14 |

145 |

75 |

7 |

|

40 |

1 1/2 |

200 |

130 |

100 |

80 |

3 |

16 |

4-Φ14 |

160 |

82 |

8 |

|

50 |

2 |

230 |

140 |

110 |

90 |

3 |

16 |

4-Φ14 |

178 |

95 |

10 |

|

65 |

2 1/2 |

290 |

160 |

130 |

110 |

3 |

16 |

4-Φ14 |

205 |

105 |

20 |

|

80 |

3 |

310 |

185 |

150 |

125 |

3 |

18 |

4-Φ18 |

230 |

120 |

25 |

|

100 |

4 |

350 |

205 |

170 |

145 |

3 |

18 |

4-Φ18 |

255 |

135 |

30 |

|

125 |

5 |

400 |

235 |

200 |

175 |

3 |

20 |

8-Φ18 |

305 |

158 |

50 |

|

150 |

6 |

480 |

260 |

225 |

200 |

3 |

20 |

8-Φ18 |

345 |

180 |

65 |

|

200 |

8 |

495 |

315 |

280 |

255 |

3 |

22 |

8-Φ18 |

415 |

215 |

137 |

|

250 |

10 |

622 |

370 |

335 |

310 |

3 |

24 |

12-Φ18 |

490 |

240 |

150 |

|

300 |

12 |

698 |

435 |

395 |

362 |

4 |

24 |

12-Φ23 |

540 |

265 |

185 |

|

350 |

14 |

787 |

485 |

445 |

412 |

4 |

26 |

12-Φ23 |

585 |

300 |

215 |

|

400 |

16 |

914 |

535 |

495 |

462 |

4 |

28 |

16-Φ23 |

625 |

360 |

244 |

|

450 |

18 |

978 |

590 |

550 |

518 |

4 |

28 |

16-Φ23 |

680 |

385 |

276 |

|

500 |

20 |

978 |

640 |

600 |

568 |

4 |

30 |

16-Φ23 |

740 |

415 |

315 |