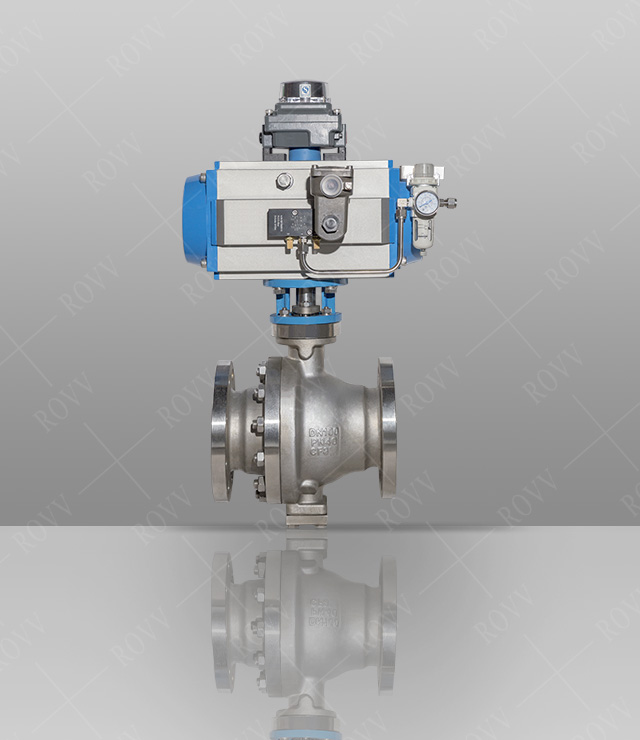

Lining Ball Valve(Pneumatic)

Technical Parameters

Product model: Q41F46/Q341F46

Nominal diameter: DN50~DN600mm

Nominal pressure: PN1.0 MPa ~1.6MPa

Applicable temperature: -29℃~150℃

Applicable medium: concentrated acid, sulfuric acid, aqua regia

Product Design Features

Fluorine lined ball valves use a ball with a circular through hole as the opening and closing element, and the ball rotates around the centerline of the valve body with the valve stem to achieve valve opening and closing. Adopting a special molding process to make the sealing surface dense and good, combined with V-shaped PTFE packing, the valve achieves zero leakage; The ball and valve stem are cast together, eliminating the possibility of the valve stem being pushed out of the pressure bearing component due to pressure changes, fundamentally ensuring safety during use; The ball valve with fluorine plastic lining layer has extremely high chemical stability. Suitable for any highly corrosive chemical medium; Adopting a full bore floating ball valve structure, it can close the element leakage within the entire pressure range, making it convenient for pipeline system cleaning and maintenance. Fluorine lined ball valves are professionally designed to control the opening and closing of various highly corrosive media, and are widely used in industries such as petroleum, chemical, dyeing, pesticide, acid and alkali production. They are currently the ideal choice for anti-corrosion valves.

Material of main parts

| NO | Part Name | Grey cast iron | WCB | Stainless acid-resistant cast steel | Ultra-low carbon stainless acid-resistant cast steel | ||

| Z | C | P | R | PL | RL | ||

| 1 | Body/bonnet | HT250 | WCB | CF8 | CF8M | CF3 | CF3M |

| 2 | Ball/Stem | WCB | CF8 | CF8M | CF3 | CF3M | |

| 3 | Lining/Seat | PCTEF(F3),FEP(F46),PFA(SolubleF4),PP,PO | |||||

| 4 | Packing gland | WCB | CF8 | CF8M | CF3 | CF3M | |

| 5 | Packing | PTFE(F4) | PTFE(F4) | PTFE(F4) | |||

| 6 | Bracket | 35 | 1Cr18Ni9Ti | 1Cr18Ni9Ti | |||

| 7 | Bolt | 35 | Cr17Ni2 | 1Cr18Ni2 | |||

| 8 | Fastening nut | 45 | 0Cr18Ni9 | 0Cr18Ni9 | |||

| 9 | Operation handle | WCB | WCB | WCB | |||

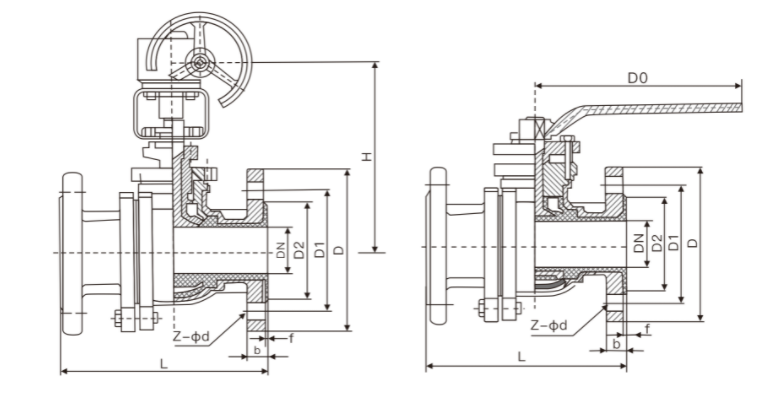

Operation handle(PN10)

|

DN(mm) |

NPS(inch) |

L |

D |

D1 |

D2 |

f |

b |

Z- φd |

D0 |

H |

WT(kg) |

| 15 | 1/ 2 | 140 | 95 | 65 | 45 | 2 | 14 | 4-14 | 120 | 80 | 3 |

| 20 | 3 /4 | 140 | 105 | 75 | 55 | 2 | 16 | 4-14 | 140 | 90 | 3.9 |

| 25 | 1 | 150 | 115 | 85 | 65 | 2 | 16 | 4-14 | 160 | 100 | 4.5 |

| 32 | 1-1 /4 | 165 | 135 | 100 | 78 | 2 | 18 | 4-18 | 160 | 110 | 6.5 |

| 40 | 1-1/2 | 180 | 145 | 110 | 85 | 3 | 18 | 4-18 | 200 | 120 | 8 |

| 50 | 2 | 200 | 160 | 125 | 100 | 3 | 20 | 4-18 | 250 | 135 | 11 |

| 65 | 2-1 /2 | 220 | 180 | 145 | 120 | 3 | 20 | 4-18 | 300 | 145 | 15.5 |

| 80 | 3 | 250 | 195 | 160 | 135 | 3 | 22 | 4/8-18 | 350 | 180 | 19 |

| 100 | 4 | 280 | 215 | 180 | 155 | 3 | 22 | 8-18 | 240 | 195 | 26 |

| 125 | 5 | 320 | 245 | 210 | 185 | 3 | 24 | 8-18 | 500 | 210 | 44 |

| 150 | 6 | 360 | 280 | 240 | 210 | 3 | 24 | 8-23 | 200* | 450 | 70 |

| 200 | 8 | 457 | 335 | 295 | 265 | 3 | 26 | 8-23 | 240* | 490 | 110 |

| 250 | 10 | 533 | 390 | 350 | 320 | 3 | 28 | 12-23 | 240* | 550 | 220 |

| 300 | 12 | 610 | 440 | 400 | 368 | 4 | 28 | 12-23 | 320* | 600 | 280 |

| 350 | 14 | 686 | 500 | 460 | 428 | 4 | 30 | 16-23 | 320* | 675 | 410 |