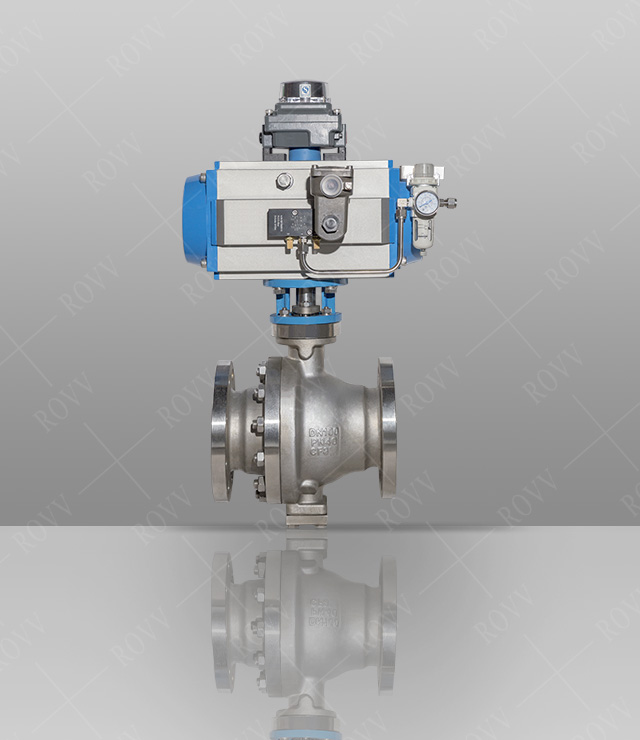

Buried fully welded ball valve

Technical Parameters

Product model: MQ61F/361F

Nominal diameter: DN150-1000mm

Nominal pressure: Class 150~400, PN1.6~6.4MPa

Applicable temperature: -29°C~200°C

Body material: carbon steel, stainless steel

Applicable medium: water, gas, oil

Operation mode: handle, worm gear

Design standard: GB/T 12237

Connection mode: GB/T 12224

Length standard: GB/T 13927

Test standard: GB/T 26480

Product description

The buried type release all-welded ball valve is mainly used in the engineering pipeline, and is used for the connection and switch adjustment of the medium. The buried relief ball valve can be directly buried in the ground or directly installed without setting up an underground valve control room. The overall structure of the buried relief ball valve adopts a fully welded industrial structure. Buried relief ball valves are widely used in urban gas underground pipelines, natural gas transmission pipelines, pressure regulating stations and other fields. The buried relief ball valve only needs to be rotated on the ground with a T-shaped handle or a transmission mechanism, which is simple and convenient.

Features

1. Buried relief ball valve, the valve body is made of seamless steel pipe and pressed into shape. The overall structure of the valve adopts a full-welding manufacturing process, which reduces external leakage, greatly reduces the weight of the valve, and is more convenient to install. Elastic gaskets and carbon fiber reinforced sealing rings are used, which can be handled by hand. Tens of thousands of reciprocating movements without leakage, ensuring the service life of the valve.

2. Buried type relief ball valve, the sealing of the valve can be used continuously under the condition of -40°C-200°C without failure. and so on. The buried relief ball valve is buried deep underground, so there is no need to set up a valve well.

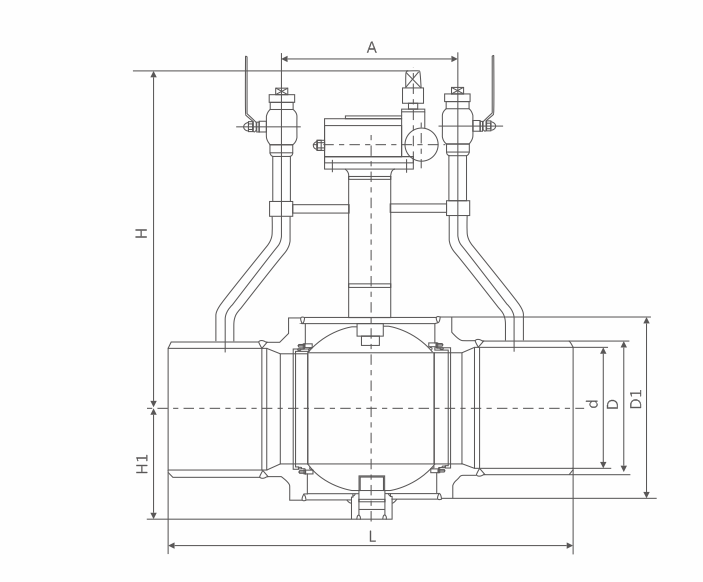

Main external connection dimensions

|

DN(mm) |

NPS(in) |

d |

D |

D1 |

L |

A |

H2 |

H1 |

|

150 |

6 |

150 |

168 |

273 |

1000 |

400 |

Customer specified

|

177 |

|

200 |

8 |

200 |

219 |

356 |

1100 |

400 |

207 |

|

|

250 |

10 |

250 |

273 |

426 |

1100 |

400 |

249 |

|

|

300 |

12 |

300 |

325 |

510 |

1230 |

500 |

298 |

|

|

350 |

14 |

334 |

356 |

560 |

1350 |

500 |

315 |

|

|

400 |

16 |

387 |

406 |

630 |

1480 |

500 |

380 |

|

|

500 |

20 |

489 |

508 |

813 |

1720 |

600 |

487 |

|

|

600 |

24 |

590 |

610 |

990 |

1800 |

650 |

578 |

|

|

700 |

28 |

686 |

711 |

1140 |

1950 |

700 |

660 |

|

|

800 |

32 |

781 |

813 |

1320 |

2150 |

800 |

752 |

|

|

900 |

36 |

876 |

914 |

1480 |

2400 |

800 |

852 |

|

|

1000 |

40 |

978 |

1020 |

1620 |

2600 |

800 |

954 |

Note: The length L of this structure is the size when the customer does not specify the length of the sleeve, and sleeves can be added at both ends according to the customer's needs, and the length of the sleeve is specified by the customer.