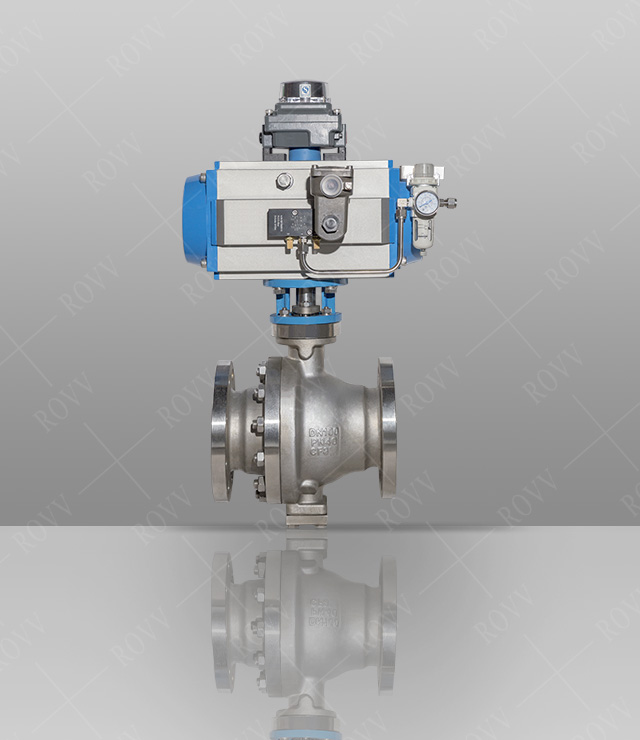

One-piece ball valve

Technical parameter

Product model: Q41F-16P Q41F-25P Q41F-40P

Nominal diameter: DN 15mm~600mm ANSI 1/2 "~24"

Nominal pressure: PN16-64

Connection form: flange, welding, thread

Body type: heavy-duty medium

Applicable temperature: -196 ℃~680 ℃

Applicable media: water, steam, oil, strong oxidizing media, urea, etc

Product Overview

The characteristics of the integrated flange ball valve are consistent with the structural length of the globe valve, plunger valve, and drain valve, expanding the range of ball valve use. The ball valve, which uses a new sealing material as the valve seat and is sealed with similar products such as polytetrafluoroethylene, has increased its service life by 3-5 times. It has the advantages of stable performance, reliable sealing, low friction, lightweight switch, high temperature resistance, wear resistance, oil resistance, corrosion resistance, and long service life. Widely used in industries such as petroleum, chemical, rubber, papermaking, pharmaceuticals, etc., it can replace globe valves, plunger valves, and quick drain valves.

Product Features

1. Low flow resistance;

2. Simple structure;

3. Small size and light weight;

4. Currently, the sealing surface material of ball valves is made of plastic, which has good sealing performance;

5. Convenient operation, quick opening and closing, and easy remote control;

6. Convenient maintenance, sealing rings are generally movable, making disassembly and replacement convenient;

7.When fully open or fully closed, the sealing surfaces of the ball and valve seat are isolated from the medium, and the passage of the medium will not cause erosion of the sealing surface of the ball valve.

Specifications

|

Design Basis |

National standard |

American Standard |

|

|

Design standards |

GB/T12237 |

API 6D |

ANSI B16.34 |

|

Structure length |

GB/T12221 |

API 6D |

ANSI B16.10 |

|

Weld |

GB/T15188.1 |

API 6D |

ANSI B16.10 |

|

Connecting flange |

GB/T9113 |

ANSI B16.5,B16.47 |

|

|

Butt welding end |

GB/T12224 |

ANSI B16.25 |

|

|

Testing and Inspection |

GB/T9092 |

API 6D |

API 598 |

Main parts and materials

|

|

Part Name |

Material |

|

|

GB |

ASTM |

||

|

1 |

Body |

WCB |

A2116-WCB |

|

2 |

Ring |

PTFE,RPP |

PTFE,RPP |

|

3 |

Ball |

1C18Ni9Ti |

SS304 |

|

4 |

Nut |

35 |

A194-2H |

|

5 |

Bolt |

35CrMoA |

A193-B7 |

|

6 |

Body |

WCB |

A216-WCB |

|

7 |

Gasket |

Flexible graphite+stainless steel |

B12.10-304F/.G |

|

8 |

Packing |

PTFE |

PTFE |

|

9 |

Packing gland |

WCB |

A2116-WCB |

|

10 |

Positioning piece |

25 |

A105 |

|

11 |

RING |

65Mn |

AISI 1066 |

|

12 |

Handle |

K33 |

A47-667 |

|

13 |

Stem |

1Cr33 |

A276-410 |

|

14 |

Screw |

35 |

A193-B7 |

|

15 |

Thrust washer |

PTFE |

PTFE |

Test pressure

|

Pressure ratingT |

Test pressure(MPa) |

||

|

Nominal pressure(PN) |

Class |

Shell Test |

Sealing test |

|

1.0 |

- |

1.5 |

1.1 |

|

1.6 |

- |

2.5 |

1.76 |

|

2.5 |

- |

3.8 |

2.75 |

|

4.0 |

- |

6.0 |

4.4 |

|

6.4 |

- |

9.6 |

7.04 |

|

- |

150 |

3.0 |

2.2 |

|

- |

300 |

7.6 |

5.6 |

|

- |

600 |

15.0 |

11.0 |

|

- |

10K |

2.4 |

1.5 |

|

- |

20K |

5.8 |

4.0 |

PN1.6MPa Main connection dimensions and weight

|

Nominal Diameter DN |

15 |

20 |

25 |

32 |

40 |

50 |

65 |

80 |

100 |

125 |

150 |

200 |

|

L |

130 |

140 |

150 |

165 |

180 |

200 |

220 |

250 |

280 |

320 |

360 |

400 |

|

H |

59 |

63 |

75 |

85 |

95 |

107 |

142 |

152 |

178 |

252 |

272 |

342 |

|

W |

130 |

130 |

160 |

180 |

230 |

230 |

400 |

400 |

650 |

1050 |

1050 |

1410 |

|

Wt(Kg) |

2.5 |

3 |

5 |

6 |

7 |

10 |

15 |

19 |

33 |

58 |

93 |

160 |

PN2.5MPa Main connection dimensions and weight

|

Nominal Diameter DN |

15 |

20 |

25 |

32 |

40 |

50 |

65 |

80 |

100 |

125 |

150 |

200 |

|

L |

130 |

140 |

150 |

165 |

180 |

200 |

220 |

250 |

320 |

400 |

400 |

550 |

|

H |

59 |

63 |

75 |

97 |

107 |

142 |

152 |

178 |

252 |

272 |

342 |

345 |

|

W |

130 |

130 |

160 |

230 |

230 |

400 |

400 |

700 |

1100 |

1100 |

1500 |

1500 |

|

Wt(Kg) |

2.5 |

3 |

5 |

6 |

7.5 |

10 |

15 |

20 |

33 |

60 |

93 |

175 |