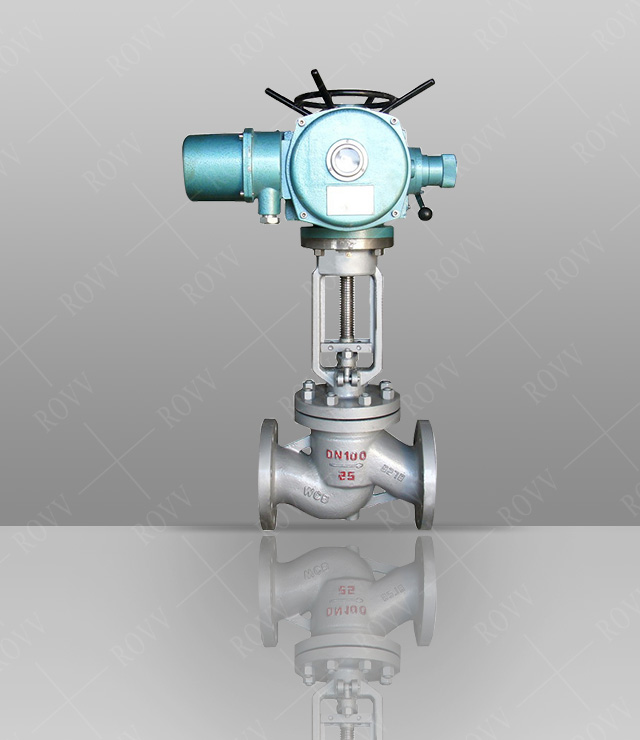

Electric globe valve

Technical Parameters

Product model: J941H/Y/W

Nominal diameter: DN50-DN300mm

Nominal pressure: PN1.6MPa-16.0MPa

Applicable medium: water, gas, oil

Applicable temperature: -20℃-425℃

Body material: carbon steel, stainless steel

Control mode: normally open, normally closed

Accessories selection: electric mechanism, manual mechanism

Product Structure Features

Electric cast steel globe valve are used to cut or connect the pipe media under pressures between PN1.6~16.0MPa, working temperatures between-46~550℃,in oil industry,chemical industry,pharmaceuticals,fertilizer,and power industry.

The main structure features include:

1.Rational structure,reliable sealing,excellent performance,pretty appearance.

2.Co- radix alloy welded sealing surface,anti-wearing,erosion-proof abrasion-proof and longer use life.

3.The surface and the adjusting media of the valve shaft are nitrogenized so that it is erosion and abrasion resistant.

4.There is backward sealing structure in the valve,so the sealing is reliable.

5.The material of the fillings and the flange sizes can be chose and matched according to the applications and the requirements of the users.That can satisfies all kinds of working requirements.

Main external connection size PN 1.6MPa

|

DN(mm) |

L |

D |

D1 |

D2 |

b |

f |

Z-φd |

H |

D0 |

|

10 |

130 |

90 |

60 |

40 |

14 |

2 |

4-14 |

198 |

120 |

|

15 |

130 |

95 |

65 |

45 |

14 |

2 |

4-14 |

218 |

120 |

|

20 |

150 |

105 |

75 |

55 |

14 |

2 |

4-14 |

258 |

140 |

|

25 |

160 |

115 |

85 |

65 |

14 |

2 |

4-14 |

275 |

160 |

|

32 |

180 |

135 |

100 |

78 |

15 |

2 |

4-18 |

280 |

180 |

|

40 |

200 |

145 |

110 |

85 |

16 |

2 |

4-18 |

330 |

200 |

|

50 |

230 |

160 |

125 |

100 |

16 |

3 |

4-18 |

350 |

240 |

|

65 |

290 |

180 |

145 |

120 |

18 |

3 |

4-18 |

400 |

280 |

|

80 |

310 |

195 |

160 |

135 |

20 |

3 |

8-18 |

355 |

280 |

|

100 |

350 |

215 |

180 |

155 |

20 |

3 |

8-18 |

415 |

320 |

|

125 |

400 |

245 |

210 |

185 |

22 |

3 |

8-18 |

460 |

360 |

|

150 |

480 |

280 |

240 |

210 |

24 |

3 |

8-23 |

510 |

400 |

|

200 |

600 |

335 |

295 |

205 |

26 |

3 |

12-23 |

710 |

400 |

|

250 |

650 |

405 |

355 |

320 |

30 |

3 |

12-23 |

789 |

450 |

|

300 |

750 |

460 |

410 |

375 |

30 |

3 |

12-23 |

925 |

500 |

Main external connection size PN2.5MPa

|

DN(mm) |

L |

D |

D1 |

D2 |

b |

f |

Z-φd |

H |

D0 |

Electric device |

|

15 |

130 |

95 |

65 |

45 |

16 |

2 |

4-14 |

- |

120 |

- |

|

20 |

150 |

105 |

75 |

55 |

16 |

2 |

4-14 |

- |

140 |

- |

|

25 |

160 |

115 |

85 |

65 |

16 |

2 |

4-14 |

- |

160 |

- |

|

32 |

180 |

135 |

100 |

78 |

18 |

2 |

4-18 |

- |

180 |

- |

|

40 |

200 |

145 |

110 |

85 |

18 |

3 |

4-18 |

- |

200 |

- |

|

50 |

230 |

160 |

125 |

100 |

20 |

3 |

4-18 |

645 |

240 |

DZW101 |

|

65 |

290 |

180 |

145 |

120 |

22 |

3 |

8-18 |

690 |

280 |

DZW101 |

|

80 |

310 |

195 |

160 |

135 |

22 |

3 |

8-18 |

715 |

280 |

DZW151 |

|

100 |

350 |

230 |

190 |

160 |

24 |

3 |

8-23 |

770 |

320 |

DZW20 |

|

125 |

400 |

270 |

220 |

188 |

28 |

3 |

8-25 |

780 |

360 |

DZW30 |

|

150 |

480 |

300 |

250 |

218 |

30 |

3 |

8-25 |

875 |

400 |

DZW45 |

|

200 |

600 |

360 |

310 |

278 |

34 |

3 |

12-25 |

967 |

400 |

DZW60 |

|

250 |

650 |

425 |

370 |

332 |

36 |

3 |

12-30 |

- |

450 |

- |

|

300 |

750 |

485 |

430 |

390 |

40 |

4 |

12-30 |

- |

500 |

- |