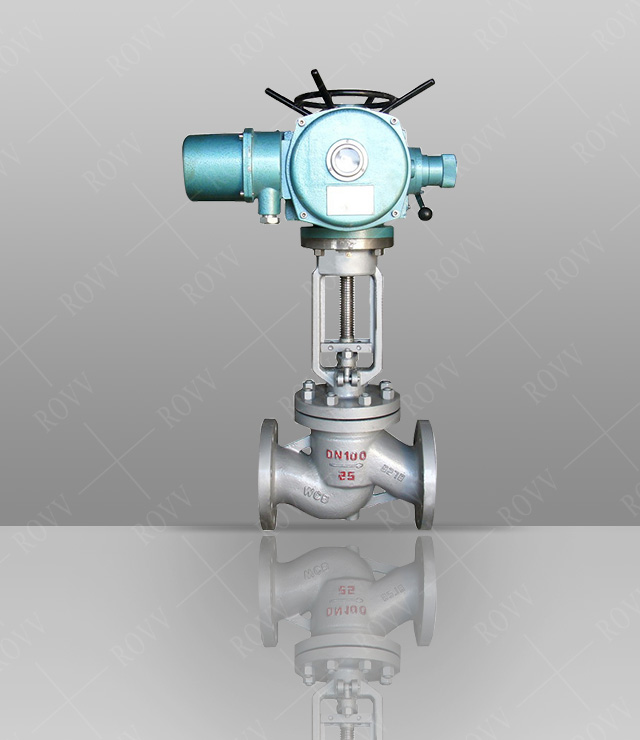

Oxygen shut-off valve

Technical Parameters

Product model: YJ41W

Nominal diameter: DN15~200mm

Nominal pressure: PN1.6~4.0MPa

Applicable medium: oxygen

Applicable temperature: 0℃-80℃

Body material: stainless steel, copper alloy

Product Description

Oxygen special globe valve is mainly used to connect or cut off the medium in the pipeline. Generally, it is not used to adjust the flow, but it is suitable for a wide range of pressures. This is a special valve specially designed for the oxygen pipeline network, which is widely used in the pipeline network of steel, metallurgy, petrochemical, chemical and other oxygen-using projects. In addition to the functions of ordinary valves, it also has its own characteristics. Strict oil-free measures are adopted during manufacture, and all parts are strictly degreased before installation. All valve flange ends are provided with conductive screw holes to prevent static electricity. The exposed parts of the valve are protected against dust and oil contamination.

Product Features

1. In addition to the functions of ordinary valves, the valve has its own characteristics.

2. Strict oil prohibition measures are adopted during manufacture, and all parts are strictly degreased before installation.

3. The flange ends of all diameter valves are provided with conductive screw holes to prevent static electricity.

4. There are protective measures for the exposed parts of the valve to prevent dust and oil pollution.

5. The materials used are divided into two categories: one is to use cast silicon brass as the material for the valve body, valve cover and valve disc; the other is to select high-quality stainless steel for the valve body, valve cover and valve disc.

Main performance and scope of use

| Model | PN | Shell test pressure Ps(Mpa) | Air tightness test | Proper temperature(℃) | Applicable media | |

| Water | Gas | |||||

|

YJ41W-25P YJ41W-40P |

2.5 | 3.8 | 2.5 | 2.5 | 0-80 | Oxygen |

Main external connection dimensions

|

DN(mm) |

L |

D |

D1 |

D2 |

b |

Z-φd |

D0 |

H |

H1 |

L1 |

|

JY41W-25P/PLJY41W-25T |

||||||||||

|

15 |

130 |

95 |

65 |

45 |

16 |

4-φ14 |

100 |

190 |

- |

- |

|

20 |

150 |

105 |

75 |

55 |

16 |

4-φ14 |

100 |

213 |

- |

- |

|

25 |

160 |

115 |

85 |

65 |

16 |

4-φ14 |

125 |

236 |

- |

- |

|

32 |

180 |

135 |

100 |

78 |

18 |

4-φ18 |

180 |

312 |

- |

- |

|

40 |

200 |

145 |

110 |

85 |

18 |

4-φ18 |

160 |

328 |

- |

- |

|

50 |

230 |

160 |

125 |

100 |

20 |

4-φ18 |

320 |

450 |

- |

- |

|

65 |

290 |

180 |

145 |

120 |

22 |

8-φ18 |

360 |

530 |

- |

- |

|

80 |

310 |

195 |

160 |

135 |

22 |

8-φ18 |

400 |

560 |

- |

- |

|

100 |

350 |

230 |

190 |

160 |

24 |

8-φ23 |

450 |

618 |

- |

- |

|

125 |

400 |

270 |

220 |

188 |

28 |

8-φ25 |

450 |

675 |

- |

- |

|

150 |

480 |

300 |

250 |

218 |

30 |

8-φ25 |

560 |

743 |

- |

- |

|

200 |

600 |

360 |

310 |

278 |

34 |

12-φ25 |

640 |

850 |

- |

- |

|

250 |

650 |

425 |

370 |

332 |

36 |

12-φ30 |

720 |

975 |

340 |

380 |

|

300 |

750 |

485 |

430 |

390 |

40 |

16-φ30 |

800 |

1115 |

340 |

415 |

|

400 |

950 |

610 |

550 |

505 |

48 |

16-φ34 |

900 |

1380 |

340 |

465 |